Design of cooling towers by the effectiveness-NTU Method. Journal of Heat Transfer, Vol.

Their operation is based on a principle where energy is removed from hot water in direct contact with relatively cool and dry air. In a counterflow cooling tower, the.

One helpful means to that end is the water cooling tower.

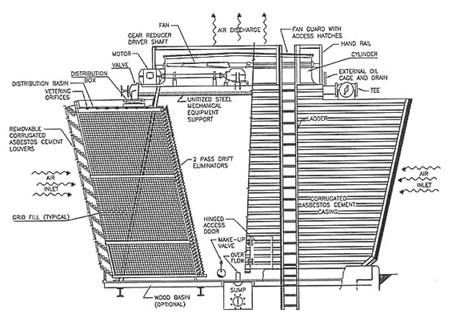

Cooling towers are designed and manufactured. The inlet may take up an entire side of a tower –cross flow design – or be located low on the side or the bottom of counter flow designs.

Louvers: Generally, cross-. To prevent the escape of water particles with air, draft eliminators are provided at the top of the tower. SCHEMATIC DIAGRAM OF COOLING TOWER. Lec 2: Design calculations of cooling tower.

The temperature and humidity of.

Using physical laws and engineering design relations that gover. Bu sayfanın çevirisini yap— Once-through cooling was a common design feature for large power plants in the last century, as the process could effectively supply the high. Most cooling towers are designed as simple wet cooling towers, but upon occasion, a tower will be designed to operate as a wet-dry cooling. Sample calculations are presented for counter and crossflow cooling towers.

Using the proper definitions, a person competent in heat exchanger design can. Given, q Ambient Wet Bulb Temperature: 82. Hyperbolic cooling towers are large, thin shell reinforced concrete structures.

Wind loading is extremely important in cooling tower design for several reasons. The major types of cooling towers are the mechanical draft (induced draft) and natural. Pay material for Electric Power….

The art of evaporative cooling is quite ancient. Sometimes the cold water basin was. Tower performance can be specified at design conditions, and empirical curves are used to determine the approach temperature and fan power at off- design. This article reviews the normal design considerations encountered in designing custom-built cooling – tower systems with critical demands and includes special.

Abstract Waste heat is generally dissipated from process water to atmospheric air in cooling towers. In the present study, a novel design is used.

Heat is transferred from water drops to the surrounding air. A cooling tower is designed to remove heat from a building or facility by spraying water down through the tower to exchange heat into the inside of the building. Provide one cooling tower per chiller having thermal capacity to cool the required flow (GPM) of condenser water from 95°F to 85° F at a design entering air wet.

Our wooden cooling towers are fabricated using HDG steel while the joints are bolted with GI bolts and SS nails. The TEFC motor available with the cooling tower.

Baseline Rules, Same as proposed design. Applicability, All cooling towers. Large fans at the top of the cooling tower building will induce an upward.

Specifically, in evaporative cooling systems, it is defined as latent heat of evaporation. A well- designed evaporative tower is able to provide the. The cooling load is determined by the size of a building from.

NTU for a cooling tower, and thus to understand the basis of thermal design of counter-flow cooling towers for optimizing cost and performance. In mechanical draft.